TECHNOLOGY

SiMaxxTM Enables Superior Energy Density for High-Performance Applications

We Enable the Future of Electric Mobility Today

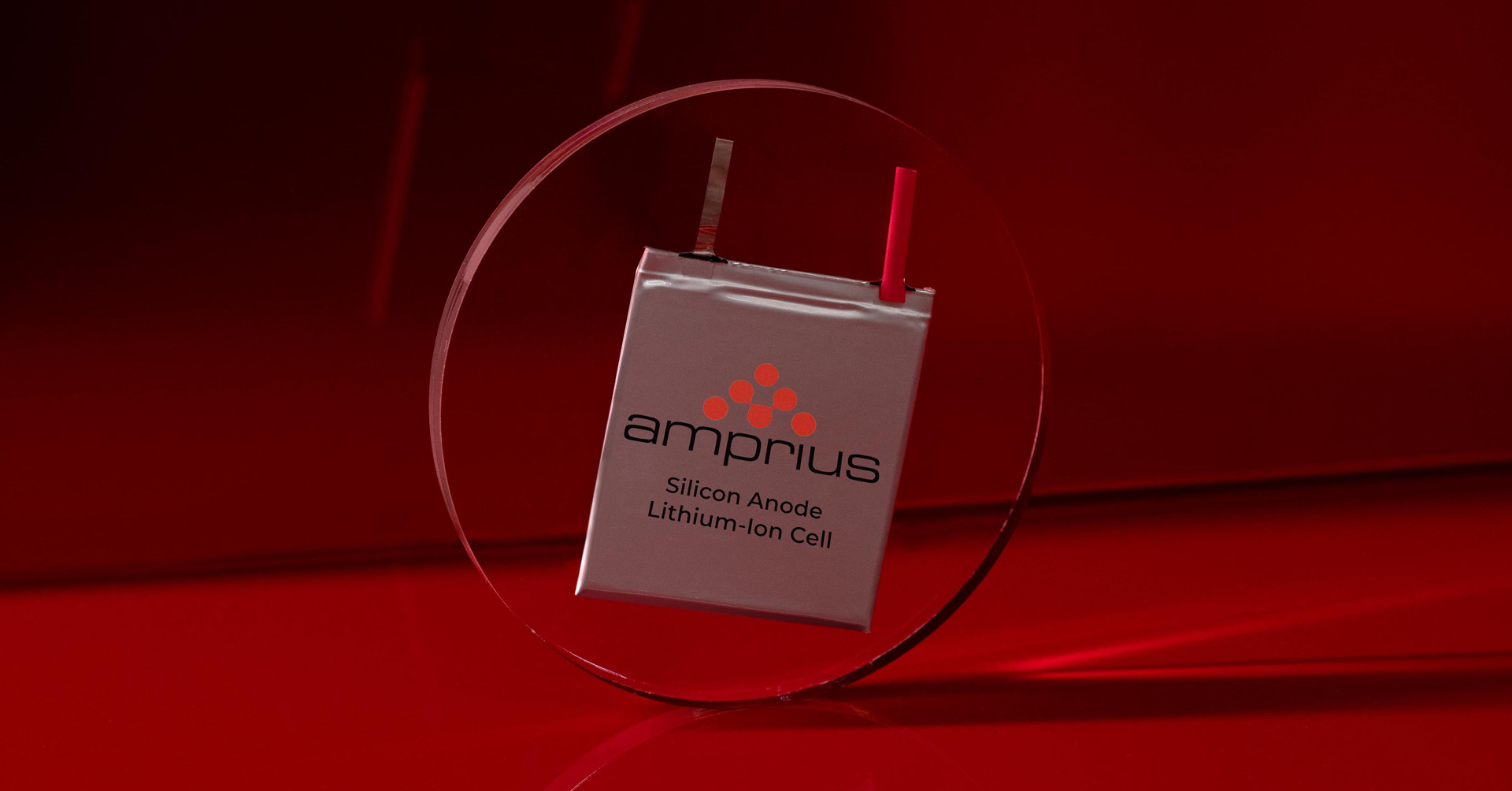

Innovation

- High performance silicon anode batteries

Superior Battery Performance

- High Energy Density

- Up to 500 Wh/kg(1) and 1,300 Wh/L(1)(2)

- High Power Density

- Up to 10C

- Fast Charge Rate Capability

- 80% charge in <6 minutes(3)

- Safety

- Passed Military Performance Spec Nail Penetration test with 390 Wh/kg

- Wide Operating Temperature

- -30°C to 55°C

Commercially Proven

- Tested and validated by industry leading partners

Note: Certain performance metrics are based on specific Amprius products.

(1) At C/10 and 23°C.

(2) Volumetric energy density is calculated using body dimensions at 30% state of charge (“SoC”).

(3) With 390 Wh/kg battery, available with SiMaxxTM

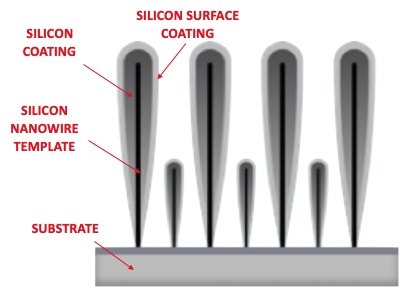

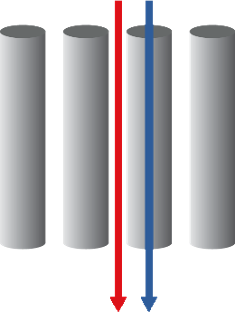

SIMAXXTM Silicon Anode Structure

100% Silicon Nanowires(1) Allow Volume Expansion without Binders, Graphite, or any Inactive Materials

Conventional Graphite Particles

- Spacing between nanowires and silicon porosity accommodate silicon volume expansion

- Ions and electrons travel straight paths

- Most conductive path for ions and electrons results in high power capability and fast charge rate

(1) Actual percentage of silicon is 99.5-99.9% which is within the range of acceptable purity levels for materials that are considered 100%.

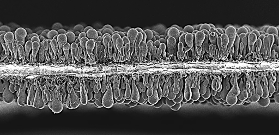

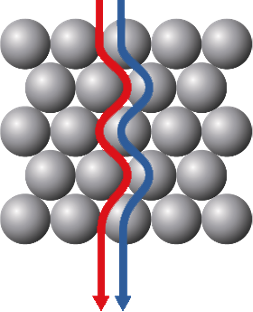

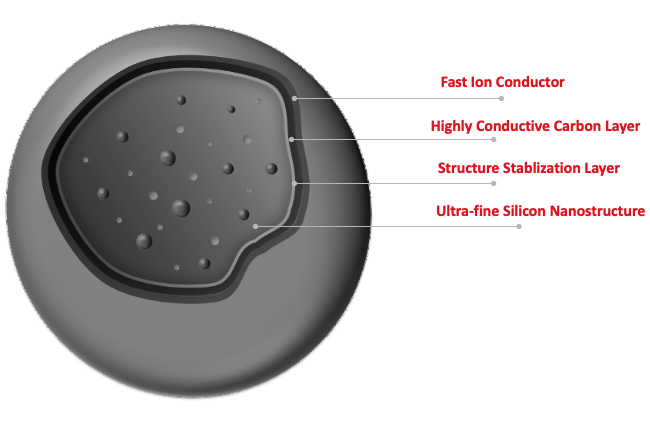

SICORETM Silicon Anode Structure

THE PROBLEM

Why is battery technology evolving so slowly?The main reason for the slow pace of battery improvement is chemistry. In conventional lithium-ion batteries the anode is made of carbon in the form of graphite, and graphite has reached its energy density limit.

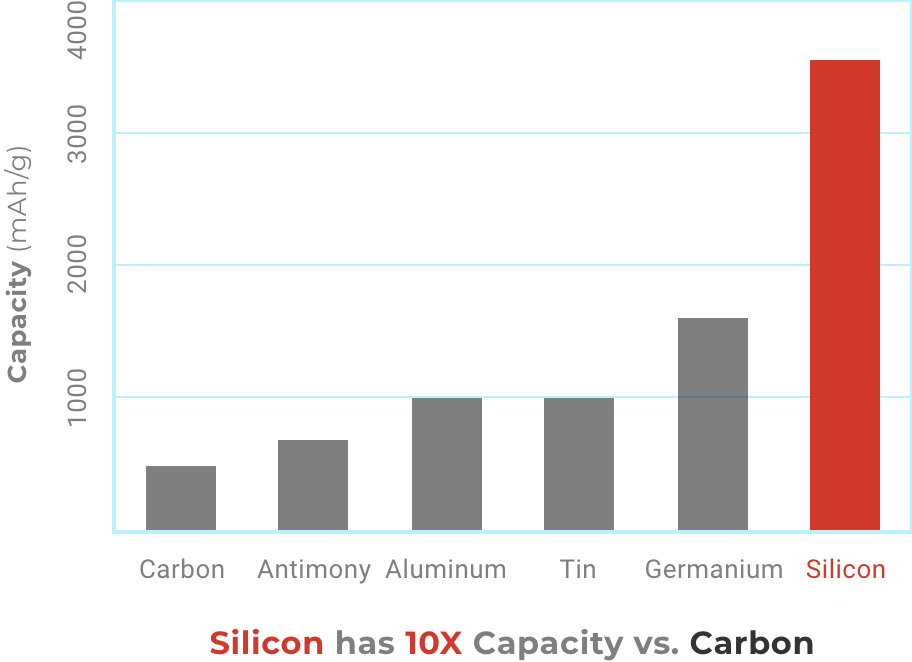

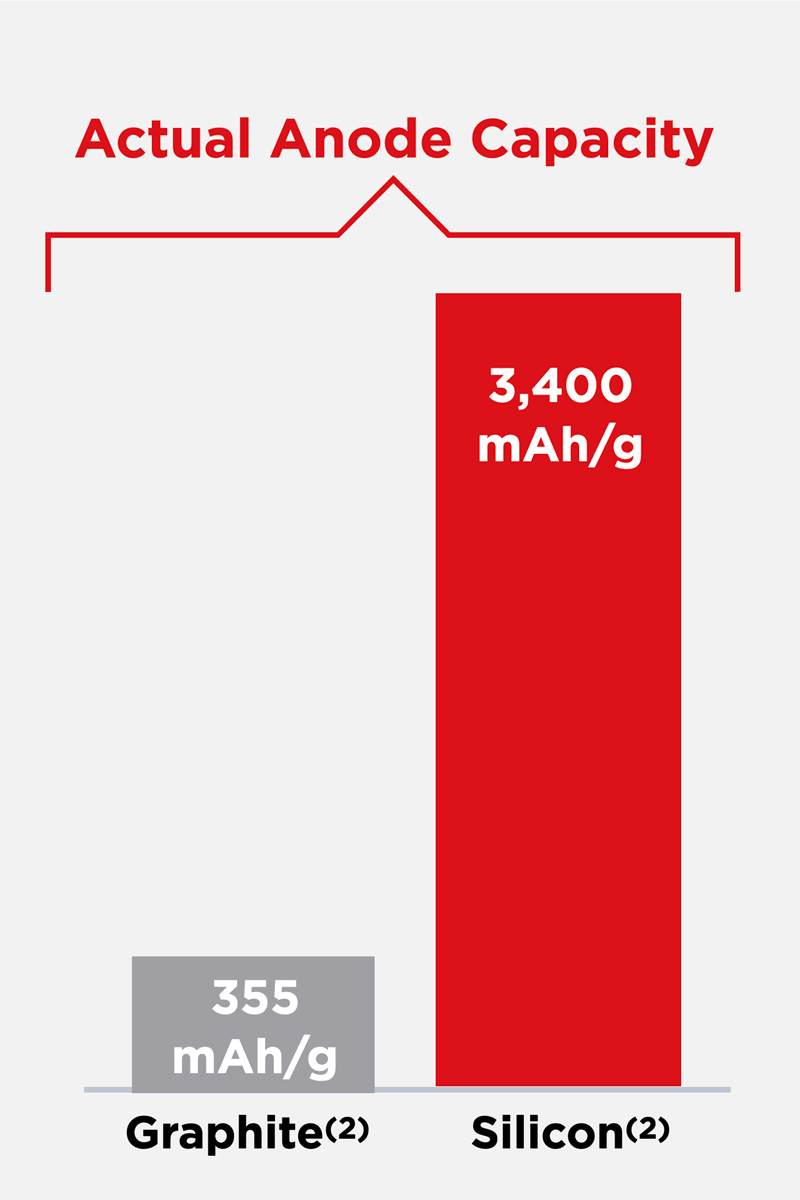

A new anode material is required to improve battery performance, and that material is silicon. Silicon can store up to 10 times more lithium compared to graphite which enables batteries to have much greater energy. But silicon swells dramatically when it is charged with lithium and that can cause it to crack and stop working.

Advantages of Amprius’ silicon batteries

Highest content active silicon material

Silicon is the best material for energy density. Using more silicon means that we can provide lithium-ion batteries with higher energy density, while at the same time enabling the highest ratio of energy to power.

Excellent cycle life

Amprius Technologies’ Silicon Batteries have excellent cycle life that is continuously improving. This has been demonstrated in real world use with multiple organizations including US National Labs and major aerospace companies.

100% Silicon Anode (1) Has ~10x Capacity vs. Graphite

(1) Actual percentage of silicon is 99.5-99.9% which is within the range of acceptable purity levels for materials that are considered 100%.

(2) Based on Amprius measurements in half cells.

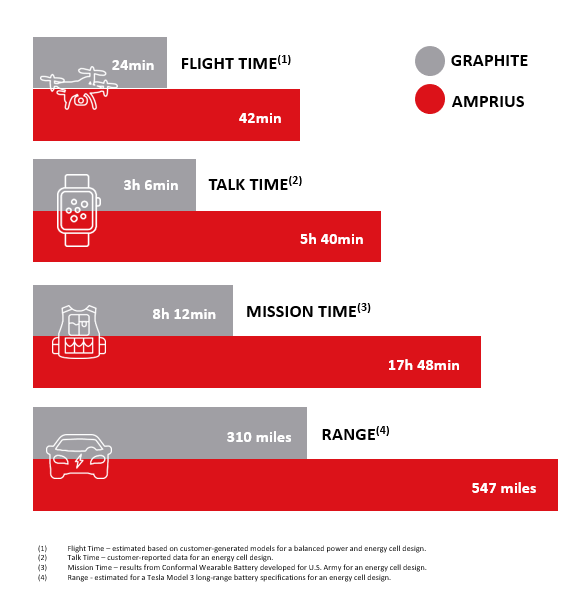

PRESENT AND FUTURE

Revolutionizing battery technologyNotes:

Urban Air Mobility – estimated flight time based on customer models

Soldier Power – real data based on Conformal Wearable Battery developed for US army

Smartwatch – customer-reported data

Electric Vehicle – estimated relative to Tesla Model 3 long-range battery specifications